| GAS SHIELDED FLUX CORED WIRES |

|

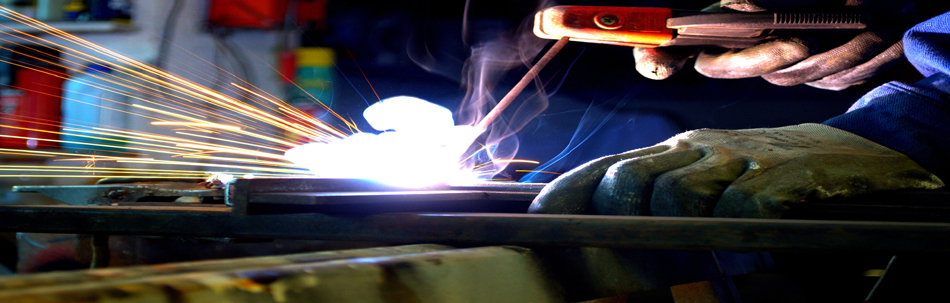

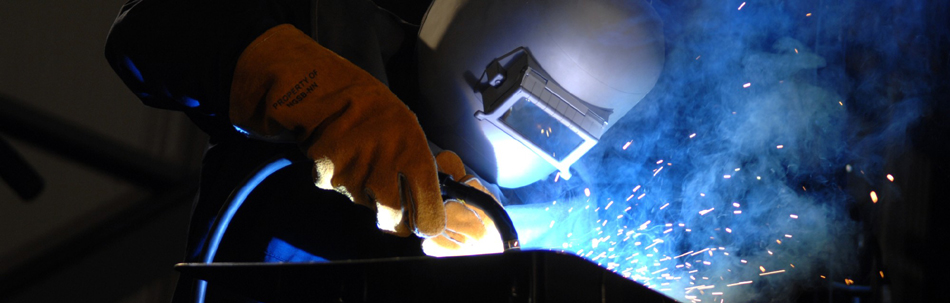

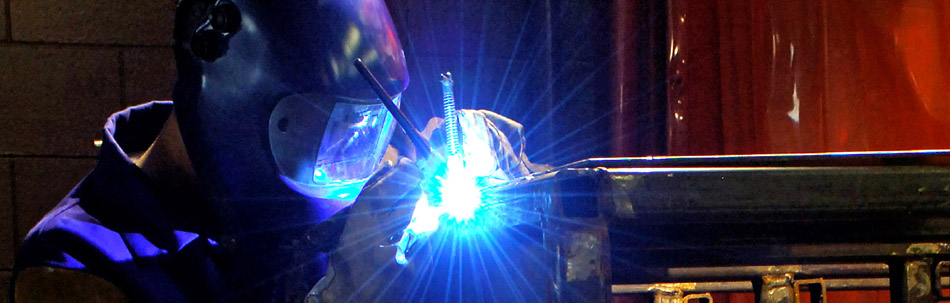

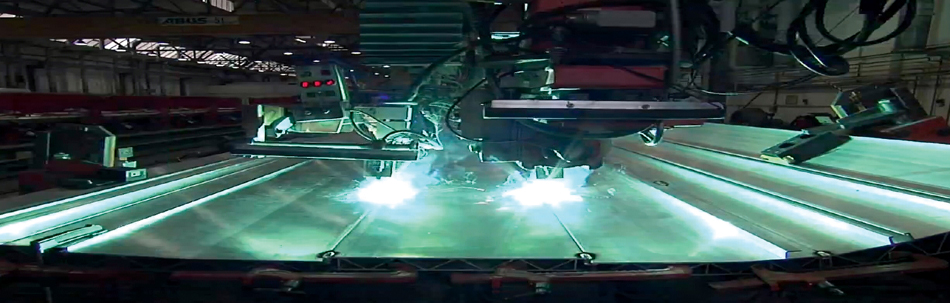

GAS SHIELDED FLUX CORED WIRES Our Gas shielded flux cored wires have a flux coating that solidifies more quickly than the molten weld material. Ideally suited for welding applications where gas shielded electrodes may have problems, such as outdoors or in windy conditions (light gauge steel plate fabrication or general purpose fabrication of carbon steels). Good choice in poor fit-up situations or when extended stick-outs must be used in hard to reach areas. Our flux cored wires are also available in various grades and can be offered on request.

ROYALFIL GS-12R (E 71 T-1) CODIFICATION : AWS A / SFA 5.20 E71T-1C APPROVED BY : LRA / ABS/ DNV/ GL/IRS /IBR/RDSO DESCRIPTION : Royalfil GS-12R is an all position Rutile flux cored wire designed for optimum performance when using CO2 shielding. The smooth metal transfer facilitates easy deposition of vertical-up stringer beads. The slag coverage is complete and designed for easy removal. Weld metal is consistently free of inclusions and porosity for X-ray soundness. This wire is formulated to produce fewer fumes, minimal spatter. APPLICATIONS : Royalfil GS-12R is designed for all position single and multipass welding of low and medium carbon steels. Suitable for joining steels conforming to ASTM SA-36 /SA-36M and A,B,C,D grades of SA-283 / SA-283M & SA-414 / SA-414M.(P.No.1) e.g. Fabrication in chemical plant machinery structures & Steel frames in ship building, heavy bridges & towers.

SHIELDING GAS : Carbon Dioxide (CO2) shielding at 15-20 lit/min. approx. RECOMMENDED STICK OUT : 15 - 20mm PACKING : 15 kgs. plastic spool.

ROYALFIL GS-15RB (E 71 T-5) CODIFICATION : AWS A / SFA 5.20 E71T-5C DESCRIPTION : Royalfil GS-15RB is an all position flux cored wire-having stable and smooth arc with good slag detachability using CO2 shield. The slag coverage is complete and easy to remove. Weld metal is consistently free of inclusions and porosity for radiography soundness. This wire is formulated to have high resistance to cracking with fewer fumes & minimal spatter. APPLICATIONS : Royalfil GS-15RB is designed for all position single and multipass welding of low and medium carbon steels. Suitable for joining steels conforming to ASTM SA-525-70, and C grades of SA-285, IS: 2002-2A & 2B IS2062, IS226 & DIN 17155 HIV e.g. Construction of bridges, Pressure vessel & Offshore structures.

SHIELDING GAS : Carbon Dioxide (CO2) shielding at 15-20 lit/min. approx. RECOMMENDED STICK OUT : 15 - 20mm PACKING : 15 kgs. plastic spool.

ROYALFIL GS-18R (E 81 T1-W) CODIFICATION : AWS A / SFA 5.29 E81T1-W2 C APPROVED BY : RDSO-IRS CLASS IV DESCRIPTION : Royalfil GS-18R is Rutile base all position flux cored wire for welding of low alloy. This wire is having stable and smooth arc with good slag detachability & excellent bead appearance with CO2 shield. This wire is designed for welding CORTON grade weather resistance steels. APPLICATIONS : Royalfil-18R is designed for welding atmospheric corrosion resistant steel as Resco, corton & ITACOR. Suitable for joining weathering grade steels conforming to ASTM SA-588, SA-242 etc.

SHIELDING GAS : Carbon Dioxide (CO2) shielding at 15-20 lit/min. approx. RECOMMENDED STICK OUT : 15 - 20mm PACKING : 15 kgs. plastic spool.

ROYALFIL GS-36R (E 80 T1-K2) CODIFICATION : AWS A/ SFA 5.29 E80T1-K2 C DESCRIPTION : Royalfil GS-36R is a low alloy rutile base flux cored wire depositing approximately 1.0-2.0% Ni & 0.20% Mo weld metal. The slag coverage is complete and designed for easy removal. Weld metal is consistently free of inclusions and porosity with very good mechanical strength. It is used for flat & horizontal welding with CO2 shield. Weld metal is of radiographic quality. APPLICATIONS : Royalfil-GS-36R is welding wire for welding of high tensile steel used in machinery, structures bridges etc. Steels welded are Hy80, Hy100. ASTM A 710, ASTM A 514 and similar high strength steels.

SHIELDING GAS : Carbon Dioxide (CO2) shielding at 15-20 lit/min. approx. RECOMMENDED STICK OUT : 15 - 20mm PACKING : 15 kgs. plastic spool.

ROYALFIL GS-41B (E 90 T5-K2) CODIFICATION : AWS A / SFA 5.29 E90T5-K2 C DESCRIPTION : Royalfil GS-41B is basic flux cored wire having stable and smooth arc with good slag detachability. It is used for flat & horizontal welding with CO2 shield. Weld metal is of radiographic quality. APPLICATIONS : Royalfil GS-41B is suitable for welding of many HSLA steels like HY-80, Naxtra 56, 63, LA60 etc. Suitable for joining steels conforming to ASTM Grade 60, Grade 65 steel of SA-515/ SA-515M Grade 55,Grade 60, Grade 65 steels of SA-516/SA-516M, all thickness range of SA-455/SA-455M etc.

SHIELDING GAS : Carbon Dioxide (CO2) shielding at 15-20 lit/min. approx. RECOMMENDED STICK OUT : 15 - 20mm PACKING : 15 kgs. plastic spool.

ROYALFIL GS-41B3 (E 90 T5-B3) CODIFICATION :AWS A / SFA 5.29 E90T5-B3 C DESCRIPTION : Royalfil GS-41B3 is basic flux cored wire having stable and smooth arc with good slag detachability. This wire is designed for welding of creep-resisting 2.25% Cr & 1% Mo steels. It is used for flat & horizontal welding with CO2 shield. Weld metal is of radiographic quality. APPLICATIONS : Royalfil GS-41B3 is designed for welding of creep-resisting 2.25% Cr & 1% Mo steel in flat and horizontal position. It is used for welding of high temperature, creep resistant Cr-Mo alloy boiler plates, pressure pipes and other pressure vessel applications. Suitable for joining steels conforming to ASTM Grade F22 of SA-182/ SA-182M & SA-336/ SA-336M,Grade T4,T22 of SA-199 / SA-1995M,Grade P22 of SA-335/SA-335M etc.

SHIELDING GAS : Carbon Dioxide (CO2) shielding at 15-20 lit/min. approx. RECOMMENDED STICK OUT : 15 - 20mm PACKING : 15 kgs. plastic spool.

ROYALFIL GS-41 R (E 91 T1-B3) CODIFICATION :AWS A / SFA 5.29 E91T1-B3 C DESCRIPTION : Royalfil GS-41R is an all position low alloy rutile base flux cored wire depositing approximately 2.25% Cr & 1.0%Mo weld metal with CO2 shielding. The slag coverage is complete and designed for easy removal. Weld metal is consistently free of inclusions and porosity for radiography soundness APPLICATIONS : Royalfil GS-41R is used for welding of similar composition of Cr-Mo steels and other creep resistant steels. It is also used for welding of high temperature & pipe steels for oil industry and for welding of steel casting (DIN 7245:GS-18CR Mo9-10) Suitable for joining steels conforming to ASTM Grade F22 of SA-182/ SA-182M & SA-336/ SA-336M,Grade T4,T22 of SA-199 / SA-1995M,Grade P22 of SA-335/SA-335M etc.

SHIELDING GAS : Carbon Dioxide (CO2) shielding at 15-20 lit/min. approx. RECOMMENDED STICK OUT : 15 - 20mm PACKING : 15 kgs. plastic spool.

ROYALFIL GS-42B (E 110 T5-K4) CODIFICATION :AWS A / SFA 5.29 E110T5-K4 C DESCRIPTION : Royalfil GS-42B is low alloy basic flux cored wire depositing 2% Ni, 0.25% Cr & 0.5% Mo weld metal. The weld deposit is of radiographic quality with very low diffusible hydrogen and stable and smooth arc with good slag detachability. It is used for flat & horizontal welding with CO2 shield APPLICATIONS : Royalfil GS-42B is designed for welding of high strength, fine grained quenched & tempered steel like N-A-XTRA 70, USS T1,T1B etc. to meet low temperature toughness as well as down to - 50ºC. It is also used for fabrication of earthmoving equipments, steel construction, crane plates and other similar application suitable for joining steels conforming to ASTM Grade C,D of SA-225/SA-225M, Grade A,B,C of SA-738/SA738M, all thickness range OF SA-612/612m ETC.

SHIELDING GAS : Carbon Dioxide (CO2) shielding at 15-20 lit/min. approx. RECOMMENDED STICK OUT : 15 - 20mm PACKING : 15 kgs. plastic spool.

ROYALFIL GS-81R (E 81 T1-B2 ) CODIFICATION :AWS A / SFA 5.29 E 81T1-B2 C DESCRIPTION : Royalfil GS-81R is an all position low alloy rutile base flux cored wire depositing approximately 1.20% Cr & 0.50%Mo weld metal with CO2 shielding. The slag coverage is complete and designed for easy removal. Weld metal is consistently free of inclusions and porosity for radiography soundness. APPLICATIONS : Royalfil GS-81R is used for welding of similar composition of Cr-Mo steels and other resistant steels. It is also used for welding of high temperature & pipe steels for oil industry.

SHIELDING GAS : Carbon Dioxide (CO2) shielding at 15-20 lit/min. approx. RECOMMENDED STICK OUT : 15 - 20mm PACKING : 15 kgs. plastic spool.

ROYALFIL GS-2C (E 316L T1-1) CODIFICATION :AWS A / SFA 5.22 E 316LT1-1 DESCRIPTION :Royalfil GS – 2C is an extra low carbon rutile coated all position stainless steel flux core welding wire with CO2 gas shielding. It gives the weld deposit of 18% Cr, 12% Ni & 2% Mo etc. It runs smoothly & gives uniform weld metal deposit with easily slag removal. The weld metal is highly resistance to intergranular corrosion . Weld metal is of radiographic quality with easy slag removal and low spatters. APPLICATIONIt is used for welding of 18% Cr, 12% Ni & 2.50% Mo steel also use for welding of AISE 316L & 317L type of stainless steel in chemical plant, paint, pulp paper & textile industries,CF-8M,CF-3M

SHEILDING GAS:Carbon Dioxide (CO2) shielding at 15 - 20 lit/min approx. RECOMMNDED STICK OUT:15-20mm. PACKING

ROYALFIL GS-2C (E 316L T1-1) CODIFICATION :AWS A / SFA 5.22 E 316LT1-1 APPROVED BY : RDSO - IRS M 46 CLASS VI DESCRIPTION :Royalfil GS – 2C is an extra low carbon rutile coated all position stainless steel flux core welding wire with CO2 gas shielding. It gives the weld deposit of 18% Cr, 12% Ni & 2% Mo etc. It runs smoothly & gives uniform weld metal deposit with easily slag removal. The weld metal is highly resistance to intergranular corrosion . Weld metal is of radiographic quality with easy slag removal and low spatters. APPLICATIONIt is used for welding of 18% Cr, 12% Ni & 2.50% Mo steel also use for welding of AISE 316L & 317L type of stainless steel in chemical plant, paint, pulp paper & textile industries,CF-8M,CF-3M

SHEILDING GAS:Carbon Dioxide (CO2) shielding at 15 - 20 lit/min approx. RECOMMNDED STICK OUT:15-20mm. PACKING 12.5 kgs. plastic spool.

ROYALFIL GS D2 (E 309L T1-1) CODIFICATION :AWS A / SFA 5.22 E 316LT1-1 DESCRIPTION :Royalfil GS-D2 is a stainless steel flux core welding wire for all position welding with co2 gas shielding. It gives the 23% Cr and 12% Ni weld deposit with excellent all around performance and resistance to chemical corrosion. Weld metal is of radiographic quality with easy slag removal and low spatters. Royalfil-GS-D2 is suitable for the welding of dissimilar metals such as stainless steel and carbon steel or stainless steel and low alloy steel.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||