| OPEN ARC FLUX CORED WIRES (HARD FACING) |

|

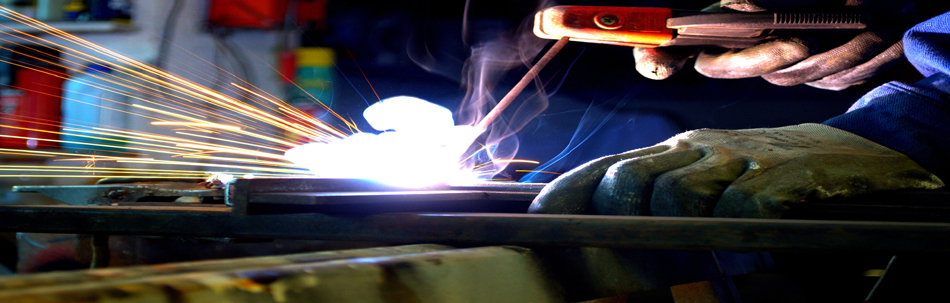

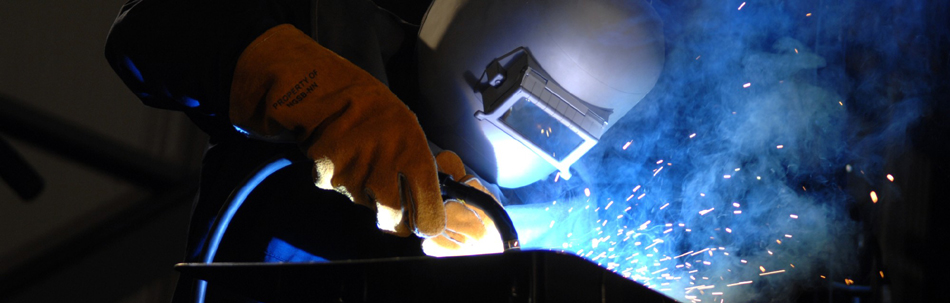

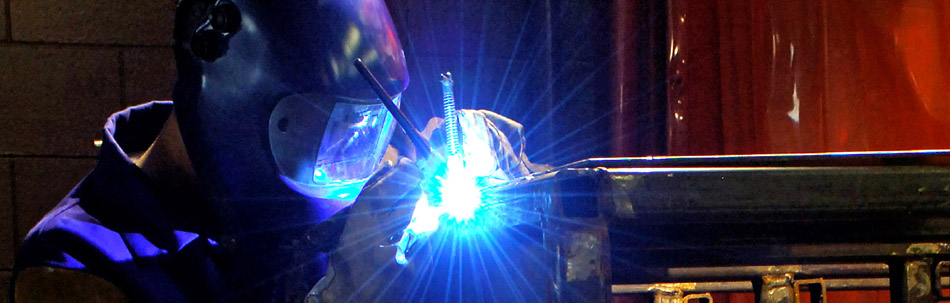

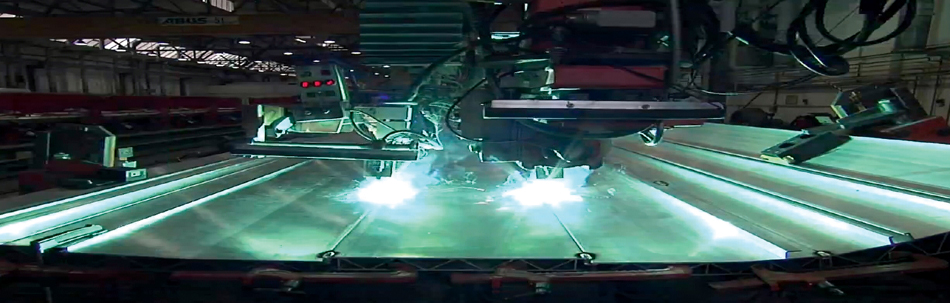

OPEN ARC FLUX CORED WIRES (HARD FACING) We offer Open Arc Flux Cored Wire for build-up and hard facing applications. Excellent build-up alloy on all weldable steels except 14% manganese steel. The weld metal is machinable and number of layers are not restricted. Some typical applications are surfacing in gears, shafts, sprockets, pinion-gear in sugar industry, rails, base layer prior to use of a more abrasive resistant overlay on palm oil expelled screws, winch drum, crawler tractor links, crane wheels, steel shafts, mine car wheels, sheaves, etc.

ROYAL - 7060 DESCRIPTION : Royal 7060 hard facing self shielded (open ARC) flux core wire deposits high chromium high carbon weld metal subjected to hard facing of component for extreme abrasion / erosion under moderate / heavy impact load. The weld deposit is nonmachinable and grinding is possible. APPLICATIONS : Hardfacing excavator parts, bucket, cutting edges grabteeth, crusher jaws & cones, table liner high chrome crusher rolls in cement plants, catalyst pipes and bends heavy load earth moving equipments etc.

Welding Parameter

ROYALFIL OA-CII DESCRIPTION : A low alloyed flux core wire designed for building up crack free weld deposit and are machinable with carbide tipped tools. Deposited weld metal gives the hardness 30 – 40HRC. APPLICATIONS : It is for rebuilding of worn machinery parts, deposit surfaces are suitable for metal to metal rolling and sliding contact of low / high speed gear teeth shaft rail links rollers, wheel etc.in Mining & Civil Engineering industries.

MECHANICAL PROPERTIES: HARDNESS ON III RD LAYER IS 30 – 40 HRC

Packing: 15 kgs. plastic spool for 1.20/1.60mm 10 Kgs. plastic spool for 2.00/2.40mm RECPMMENDED STICK OUT: 20 - 40 mm

ROYALFIL OA-CIII DESCRIPTION : A high carbon& high chrome flux core wire depositing a weld metal having excellent resistant of abrasion friction and moderate impact. A deposited weld metal gives Hardness 55 to 60 HRC. APPLICATIONS :Suitable for surfacing of minerals craine wheels hot & cold punching dies metal cutting & forming tools, crush hammer & catter pillers trades, crane wheels, conveyer buckets. Self tempering deposit for hard facing applications in Mining & Civil Engineering industries.

MECHANICAL PROPERTIES:HARDNESS ON III RD LAYER IS 55 – 60 HRC.

Packing: 15 kgs. plastic spool for 1.20/1.60mm 10 Kgs. plastic spool for 2.00/2.40mm RECOMMENDED STICK OUT: 20 - 40 mm

ROYALFIL OA-CV DESCRIPTION :A high carbon& high chrome flux cored wire depositing air hardfnening weld metal is of approx 58 to 62 HRC. The weld metal is resistant to severe abrasion and moderate impact. APPLICATIONS :Suitable for hard facing application like Dredger bucket lips, teeth, shaves, excavator, conveyer bucket cutting edges etc.

MECHANICAL PROPERTIES:Hardness on III rd Layer is 58 – 62 HRC. Current / Polarity:DC Wire Positive

Packing: 12.50kgs. spool in polythin bag and shrikataped in corrugated box.

ROYALFIL OA 307 DESCRIPTION : Royalfil OA - 307 is a Self Shielded rutile coated multi purpose stainless steel flux cored wire for all position welding. The weld metal has excellent crack resistant & heat resistance at 900ºC . It is also corrosion resistant to Atmosphere marine water and weak acids. It gives 18%Cr, 8% Ni, 6% Mn type weld deposit with easily slag removable. Applications:Suitable for joining ferrtic to austenitic steel, Armour plates, Heat resistant steel, dissimilar steel, Buffer layer on difficult steel before hardfacing, excellent for repairing cracks in austenitic manganese steel casting for surfacing manganese steel.

Welding Parameter: Dc Wire Positive

Packing:12.50kgs. spool in polythin bag and shrink packed corrugated box.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||